What are Automotive Specified Ceramic Coatings?

Understanding Automotive Paint Surface

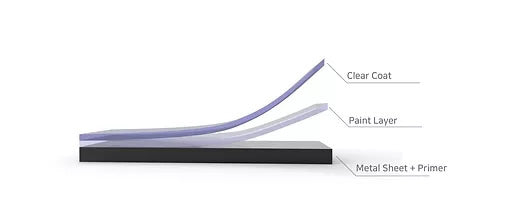

Automotive paint surface is largely divided into 3 layers.

The first layer is the metal sheet + a layer of primer. The 2nd

layer is covered with actual paint, which will reflect car’s colour.

In the final layer, a thick layer of clear coat is applied to protect the surface.

The most important layer is the clear coat layer. Due to its natural characteristics, clear coats tend to absorb anything under specific sizes. This is why often times pollutants end up sinking into the clear coat if they are not removed for a long time.

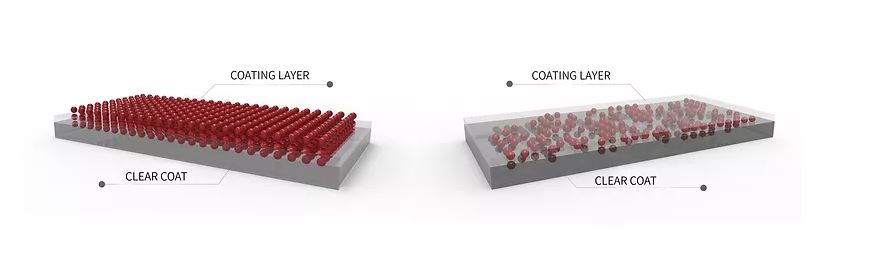

Making the ceramic coating bond with the clear coat as firmly as it can is the main key to having the ceramic coatings last long. In order to do this we have to make the size of the molecule as small as we can, maximized the molecule density, and at the same time consider how and when the ceramic coatings will be used

False marketing

These properties lead to two problems that are commonly misused for marketing

1. Often times, many detailing shops will promote products by pouring the product into a beaker and showing how it turns into a solid glass like material. However, these solid type coatings have large molecule size and does not often penetrate deep into the clear coat. Thus, it is hard to expect firm bonding to the clear coat, and if these coatings are applied to thick stains will form. Also, even after curing, pollutants will easily be absorbed into the layer and scratches and swirls marks are easily formed.

2. Sometimes, detailing shops will use paint thickness measuring tools to show how thick the coatings have been applied. No matter how precise the paint thickness measurement tools are it is hard to find an exact data because clear coats are not evenly applied. Also, most high-end coatings will be absorbed into the clear coat and thus will be impossible to correctly measure the thickness. If detailing shops use a thick coating for measurement, the coating will show problems mentioned in number 1.